What is a cooling tower and how does it work?

A cooling tower is an essential component in various industrial processes. It helps regulate temperatures by removing heat from water. This process is crucial in power plants, manufacturing, and HVAC systems.

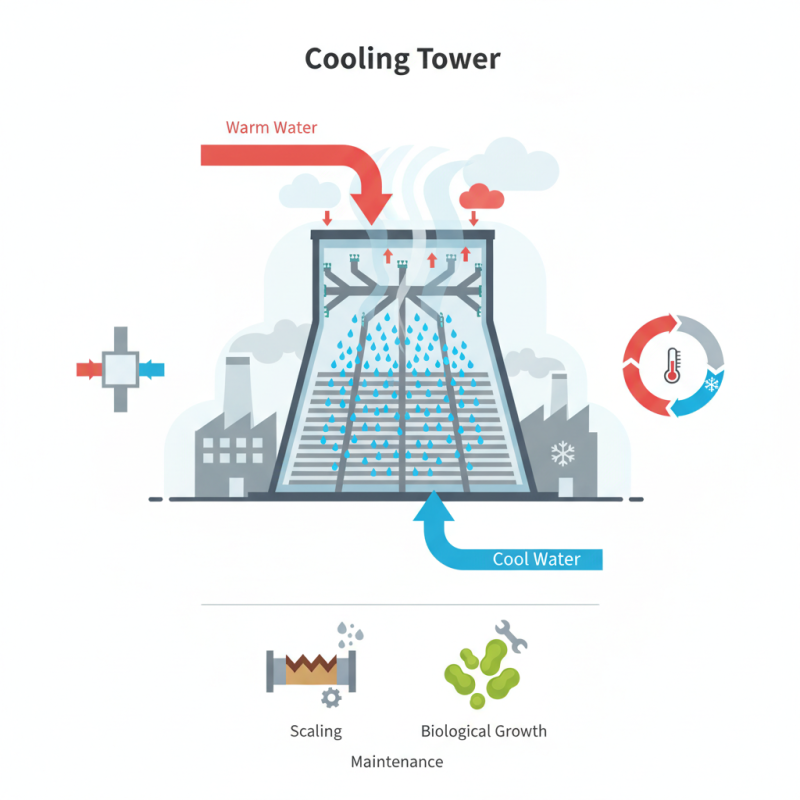

In a cooling tower, warmer water from equipment enters the tower. The heat dissipates into the air, allowing cooler water to circulate back. It’s interesting how this system is both simple and complex.

However, not all cooling towers are efficient. Some struggle with scaling or biological growth. Regular maintenance is needed to optimize operation. Understanding how a cooling tower works can lead to significant improvements.

What is a Cooling Tower? Definition and Overview

A cooling tower is an essential component in industrial processes and HVAC systems. It helps remove heat from buildings or machinery. By using water and air, the cooling tower cools down the heated water to maintain optimal temperatures.

The operation of a cooling tower is simple yet effective. Hot water is pumped to the top of the tower, where it spreads across a fill material. As water flows down, it meets cool air drawn in from the sides. This interaction allows heat to dissipate, effectively cooling the water. Wind and evaporation play key roles in this process.

One might overlook the importance of routine maintenance. Debris can clog filters, impacting performance. Regular checks are necessary to ensure optimal efficiency. The design of cooling towers can vary, leading to differences in effectiveness. Some may not achieve the desired cooling rates. Understanding these nuances can improve system efficiency and reliability.

The Working Principle of Cooling Towers: Heat Transfer Mechanisms

Cooling towers play a vital role in industrial processes. They operate primarily on the principles of evaporative cooling. The mechanism effectively transfers heat from water to the atmosphere. This process relies on two key actions: evaporation and convection.

The hot water enters the tower and is dispersed into small droplets. As these droplets fall, they come into contact with the cooler air, promoting heat transfer. As water evaporates, it absorbs heat, thereby cooling the remaining water. Data suggests that these systems can achieve up to 85% efficiency in heat exchange, making them essential for energy conservation in large facilities.

Tips: Regular maintenance is crucial. Inspecting fans and nozzles can prevent efficiency losses. Monitoring water quality is also important to avoid scaling and fouling, which can degrade performance.

While cooling towers are effective, they can pose environmental challenges. Water vapor can lead to drift, and chemical treatment can impact local ecosystems. Review local regulations to ensure compliance. It's essential to balance efficiency with environmental responsibility in cooling tower operations.

Types of Cooling Towers: Natural Draft vs. Mechanical Draft

Cooling towers are essential for regulating temperature in industrial settings. They come in two primary types: natural draft and mechanical draft. Each has distinct characteristics and applications.

Natural draft cooling towers rely on buoyancy to circulate air. Warm air rises, creating a vacuum that pulls in cooler air. This design is often used in large power plants. According to industry reports, natural draft towers can achieve an efficiency of over 90% in optimal conditions. They typically require less energy to operate. However, they need significant space and are not suitable for every location.

Mechanical draft cooling towers, on the other hand, use fans to force air through the system. This type allows for more control over airflow and is often used in commercial buildings. They can be installed in tighter spaces. However, they consume more electricity due to fan operation. Reports suggest that mechanical draft systems can achieve efficiencies around 80-85%. Maintenance can be an issue as fans and motors require regular checks.

Both systems have their advantages and limitations. Choosing between them can be challenging. Space availability, energy efficiency, and operational costs should guide the decision. Each facility must weigh these factors carefully.

Efficiency Metrics: Measuring Cooling Tower Performance

Cooling towers are essential for many industrial processes. Their efficiency directly impacts energy consumption and operational costs. To evaluate a cooling tower's performance, several metrics are vital, including cooling capacity, water consumption, and energy use. A report by the U.S. Department of Energy highlights that inefficient cooling systems can waste up to 30% of electricity—an alarming statistic for many facilities.

Cooling capacity is a key indicator. It measures how effectively a tower can dissipate heat. The cooling range, the temperature difference between inlet and outlet water, is another important measure. Ideally, a cooling tower should achieve a high cooling efficiency while minimizing water loss. According to industry standards, a well-designed cooling tower can achieve an efficiency rate of 80-90%. Yet, many towers underperform due to poor maintenance or design flaws.

Water consumption also deserves attention. Cooling towers often use vast amounts of water, resulting in higher costs and environmental concerns. Many reports indicate that evaporative cooling systems can reduce water usage by 30%. However, not all towers are optimized, leading to waste. Reflecting on these metrics can help operators identify gaps in efficiency. Addressing these shortcomings is vital for sustainability and cost-effectiveness in the long run.

Applications of Cooling Towers in Various Industries

Cooling towers play a crucial role in various industries. They help manage heat produced during industrial processes. Electricity generation, for instance, relies on cooling towers for efficient operation. In this case, they cool steam that has powered turbines. Without them, systems could overheat and fail.

In HVAC systems, cooling towers are essential too. They regulate indoor environments in large buildings. These towers absorb heat from circulating water, releasing it into the air. This process keeps facilities comfortable during hot weather. However, their performance depends on correct design and maintenance. Neglect could lead to inefficiencies.

Other applications include food processing and chemical manufacturing. Cooling towers maintain optimal temperatures for product preservation. In these sectors, any temperature fluctuation can lead to spoilage. Companies must regularly assess their cooling systems. Even small issues can escalate into bigger challenges if overlooked.

What is a cooling tower and how does it work? - Applications of Cooling Towers in Various Industries

| Industry | Application | Cooling Method | Key Benefits |

|---|---|---|---|

| Power Generation | Condensation of steam in cooling systems | Evaporative cooling | Increased efficiency, reduced water usage |

| HVAC | Air conditioning systems | Cooling through air-wash | Comfortable indoor environment, energy savings |

| Chemical Processing | Cooling of heat exchangers | Closed-loop cooling | Process stability, safety improvements |

| Food and Beverage | Manufacturing processes requiring temperature control | Indirect cooling | Quality preservation, reduced spoilage |

| Petrochemical | Heat removal during refining processes | Crossflow cooling | Enhanced productivity, cost reduction |